Structural principles and production processes of alkaline and PEM electrolyzers

Electrolyzers can be divided into four types: ALK, PEM, AEM, and SOEC according to water electrolysis technology. This article mainly introduces the structural principles and production processes of alkaline and PEM electrolyzers.

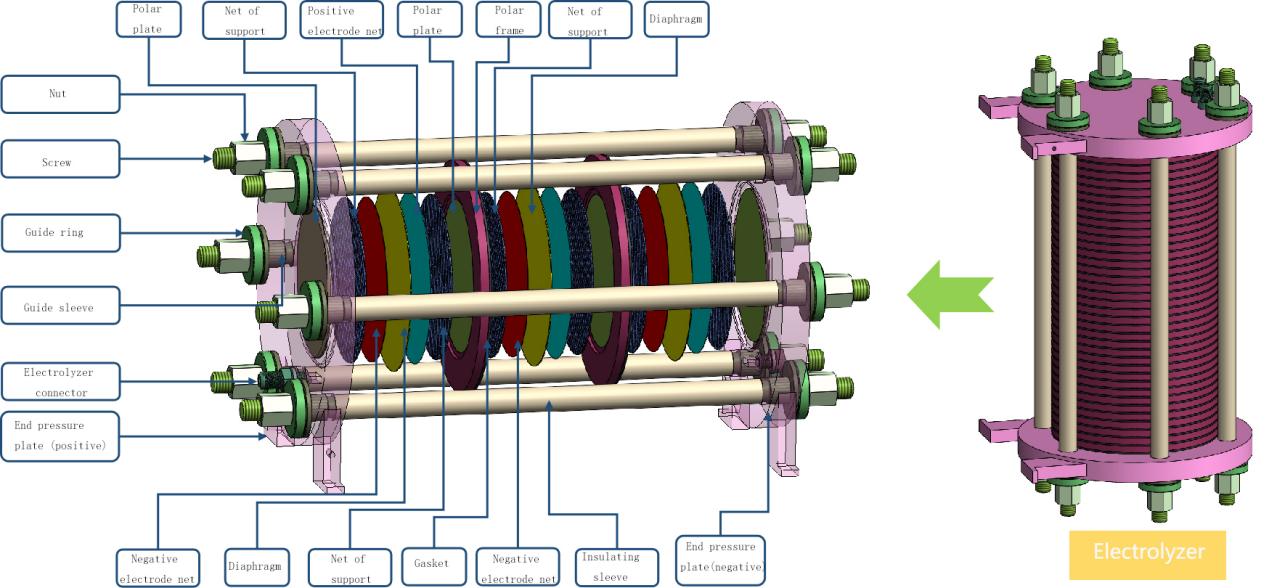

The structure of the alkaline hydrogen production electrolyzer mainly includes diaphragm, positive/negative electrode grid, electrode plate, electrode frame, gasket, fastening screw and nut, end plate, etc.

The assembly of an alkaline electrolyzer is similar to a hydrogen fuel cell stack. On the basis of the end plates, the plates, support nets, negative electrode nets, separators, positive electrode nets, support nets, pole frames, and gaskets are assembled one by one, repeat this, and finally install the end plate at the other end and fix it with the fastening screw.

Electrodes, separators and gaskets are key materials for alkaline electrolyzers. The electrodes usually use nickel mesh or nickel foam, whose performance has a decisive impact on the current density and electrolysis efficiency, and its cost accounts for about 28% of the system cost; the separator is used to separate the two poles, and it is required to ensure air tightness while reducing resistance. To reduce power loss, sealing gaskets are used to solve the insulation problem between pole pieces. Its insulation performance has an impact on electrolysis efficiency, safety, and system service life.

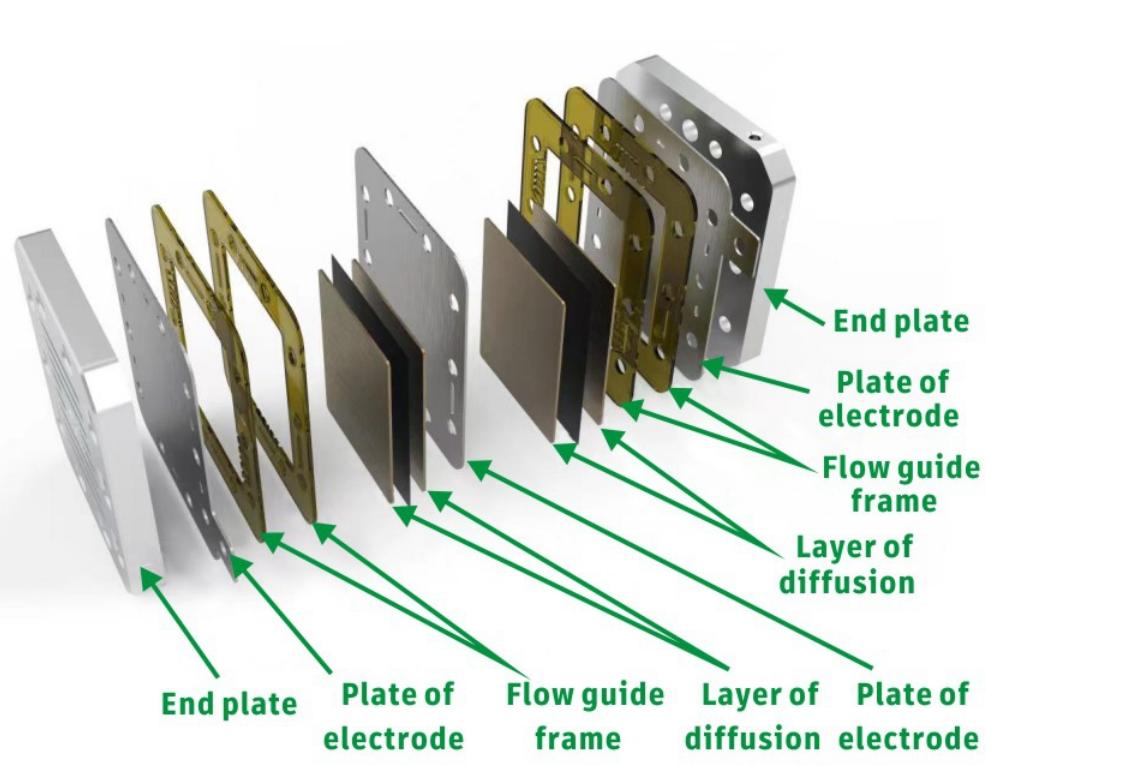

PEM electrolyzer uses proton exchange membrane as electrolyte, which has certain advantages in structure and performance. PEM electrolyzers are also stacked by multiple electrolysis units, each unit consisting of a proton exchange membrane, catalyst, gas diffusion layer and bipolar plate.

PEM electrolyzers use proton exchange membranes as solid electrolytes, replacing the separators and liquid electrolytes (KOH solutions) used in alkaline electrolyzers. The internal resistance is smaller, the internal structure is more compact, the electrolysis efficiency is greatly improved, and the scale selection is more flexible.