What Are You Looking For?

Effect of PEM Catalyst Platinum Loading on Fuel Cell Performance

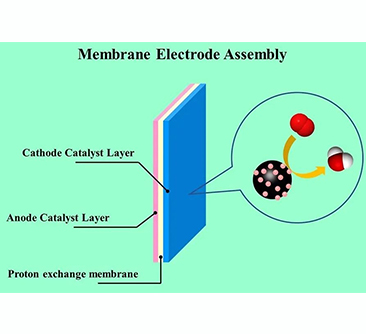

Over the past two decades, extensive research on the development of low-temperature polymerelectrolyte-membrane fuel cells (PEMFC) resulted in significant increases in the voltage performance of membrane electrode assemblies (MEAs) . These voltage gains were primarily produced by the implementation of thinner membranes, progressing from the originally most common 1100 EW (equivalent weight (gpolymer/molH+)) Nafion® membranes with thickness of 175 μm/125 μm (Nafion 117/115), to 50 μm thick Nafion® 112 , all the way to ultra-thin homogeneous (e.g. 25 μm, 1100 EW membranes extruded in the sulfonylfluoride-form from DuPont and hydrolyzed to proton-form by Ion Power ) or lower-EW PTFE/ionomer composite membranes (either from Asahi Glass (30 μm, 910 ) or Gore (25 μm, <1000 EW )) which produce high cell voltages at current densities ≥1 A/cm2. These cell voltage improvements were accompanied by significant reductions in MEA platinum loadings from the high loadings of 5–10 mgPt/cm2 per MEA in the early 1990s to <1 mgPt/cm2 per MEA in later work , a development which was primarily due to the substitution of Pt-black catalysts with higher surface area carbon-supported Pt catalysts as well as the use of perfluorosulfonic-ionomer binder in thin-film catalyst layers.

Due to these innovations in materials and processing technology, state-of-the-art fuel cells yield cell voltages which surpass older MEA technology, where only up to 0.60 V were achieved at 1.0 A/cm2 under high pressure conditions (300 kPaabs) with fully humidified H2/air reactants (stoichiometric flows of 1.5/2.0) at cell temperatures of 70–80 °C and Pt loadings of <1 mgPt/cm2 per MEA . This is, for example, illustrated by reports from UTC Fuel Cells, where 0.68 V are obtained at the same current density (1.0 A/cm2) even at ambient pressure under otherwise similar conditions (65 °C cell temperature, fully humidified H2/air at stoichiometric flows of 1.25/2.0) . In the latter case, rather low Pt cathode loadings of 0.4 mgPt/cm2 were used and Pt loadings on the anode were probably of the same value or lower (not cited). While this represents a major development progress, the Pt-specific power density still equates to ca. 0.9–1.2 gPt/kW (assuming anode Pt loadings of 0.2–0.4 mgPt/cm2, i.e. total loadings of 0.6–0.8 mgPt/cm2 per MEA), which may be sufficiently low for low-volume applications (e.g. stationary, uninterrupted-power supply, etc.), but is still too high for automotive applications, where less than 0.4 gPt/kW are required for large-scale implementation.

Primarily two approaches may be used to reduce the Pt metal requirement in state-of-the-art fuel cells: (i) reduction of the mass-transport losses particularly at high current densities by improved diffusion media (DM), improved reactant flow-fields, and improved electrode structures and/or (ii) improved catalysts and catalyst utilization. The former approach would allow to increase the stack current density to 1.5–2.0 A/cm2 with no or insignificant voltage penalty , thereby reducing the Pt-specific power density by a factor of 1.5–2 (i.e. 0.45–0.6 gPt/kW). Any further reductions would have to be achieved by a reduction of the Pt loading of the MEA below the above 0.6–0.8 mgPt/cm2 per MEA, which may either be done via platinum thrifting or the implementation of alternative catalysts (e.g. Pt-alloy cathode catalysts).

The present work examines in detail the effect of platinum loading reductions (both anode and cathode) on fuel cell performance and seeks to demonstrate the trade-off between Pt-catalyst loading and cell voltage. This will be illustrated by means of 50 cm2 single-cell data complemented by full-active-area short stack (250 and 500 cm2 active-area, ca. 20 cells) measurements. Owing to the high catalytic activity of Pt toward H2 electro-oxidation (exchange-current densities, i0, of the order of 10−3 A/cmPt2), we will show that there is a large potential for reducing Pt anode loadings in the case of fuel cell operation with pure H2, while much less reductions are achievable with current PtRu-anode catalysts in the case of fuel cell operation with CO-contaminated reformate. Unfortunately, the oxygen reduction reaction (ORR) kinetics on Pt are approximately six orders of magnitude slower than the H2 oxidation kinetics (i0 of the order of 10−9 A/cmPt2 ), and we will show that further reductions in cathode Pt loadings with pure Pt-catalysts result in well predictable voltage losses (these may, however, be avoided by implementing more advanced Pt-alloy cathode catalysts ).